High-Voltage Capacitor Safety Handling Guide

High-Voltage Capacitor Safety Handling Guide

High-voltage capacitors, capable of storing enormous electrical charges, are vital to a wide range of equipment, from industrial power supplies to medical imaging devices. However, with great power comes great responsibility, and handling these components requires a deep awareness of safety.

When handling high-voltage capacitors, strict safety procedures must be followed: disconnect the capacitor branch circuit before power is restored, and reconnect the capacitor circuit after power is restored. Do not restore power until the fuse has blown and the cause has been determined. Never reconnect the capacitor circuit with a charge. Commissioning should be based on a comprehensive assessment of reactive power flow, power factor, and voltage. If the voltage exceeds 1.1 times the rated value or the temperature exceeds 40°C, the capacitor must be shut down.

Ignoring proper handling procedures can have serious consequences, including electric shock, burns, and even explosion. In this safety handling guide, we'll delve into the world of high-voltage capacitors, exploring their types, applications, and, most importantly, the comprehensive safety procedures required for safe handling, testing, and storage. We'll cover everything from safe discharge methods to essential personal protective equipment, ensuring you have the necessary knowledge to confidently and safely operate these powerful devices.

1.0 High-Voltage Capacitor Safety Guide

1.1 How to Safely Test High-Voltage Capacitors

Testing high-voltage capacitors must be performed with the utmost caution. Before testing, ensure the capacitor is fully discharged. Once discharged, you can use a multimeter with a capacitance setting to test the capacitor.

Here are the steps to safely test high-voltage capacitors:

Fully discharge: Double-check that the capacitor is fully discharged. Use a voltmeter to confirm that the voltage across the terminals is zero.

Isolate the capacitor: If the capacitor is in a circuit, completely disconnect it to prevent interference from other components.

Set up the multimeter: Select the capacitance setting on your multimeter. If your multimeter doesn't have this feature, you can use the resistance setting to check for shorts, but this will not display the capacitance value.

Connect the probes: Connect the multimeter probes to the capacitor terminals. For simple capacitance tests, polarity is not important.

Read the measurement: The multimeter will display the capacitance reading. Compare it to the value printed on the capacitor. A reading within tolerance (typically ±10-20%) indicates the capacitor is good.

Important: Never touch the capacitor terminals with your bare hands (touching a live, high-voltage capacitor can be life-threatening).

Even after the capacitor has discharged, always wear insulating gloves and shoes, keep your hands dry, and avoid direct contact with live parts.

1.2 Safety Function of Capacitor Bleeder Resistors

The core safety function of capacitor bleeder resistors is to prevent electric shock by controlling the capacitor's discharge rate. They are a common and critical safety component in high-voltage capacitor circuits. Their operating principle is based on the exponential decay characteristics of an RC discharge circuit.How it works is as follows:

Parallel Connection: A bleeder resistor is connected in parallel with the capacitor.

Continuous Discharge Path: When the circuit is energized, a small amount of current flows through the resistor. After power is removed, the resistor provides a continuous discharge path for the capacitor.

Size is Key: The resistor value must be carefully selected. It must be high enough to avoid interfering with the normal operation of the circuit, yet low enough to discharge the capacitor within a reasonable time.

Typical Application Scenarios

New Energy Vehicles: Used in conjunction with DC-Link capacitors to absorb high pulse currents and prevent inverter overvoltage.

Industrial Equipment: For example, filter capacitors in rectifier circuits can be safely discharged by connecting a high-value resistor in parallel.

Tip: Always visually inspect the bleeder resistor for any signs of damage or burnout. A faulty bleeder resistor can create a false sense of security.

1.3 Causes of High-Voltage Capacitor Explosion

Although rare, high-voltage capacitors can explode with great force. The core cause of these explosions is internal insulation failure, leading to a short circuit. This can manifest as an internal phase-to-phase or inter-electrode short, instantly generating intense heat and gas pressure, causing the casing to burst.The following are some common causes:

Overvoltage: Applying a voltage exceeding the capacitor's rated value can cause dielectric breakdown, resulting in a short circuit and rapid energy release.

Reverse Polarity: In electrolytic capacitors, incorrect polarity connection can cause a chemical reaction, generating gas, leading to increased pressure and explosion.

Internal Fault: A phase-to-phase or inter-electrode short generates arcing, which rapidly expands the gas and causes an explosion. Manufacturing defects or aging can cause internal shorts or dielectric material degradation.

Overheating: Overheating can also cause dielectric failure.

External Environment: High temperatures, poor ventilation, or dusty environments can accelerate insulation aging.

Safety Tips: Always ensure that you use capacitors with the correct voltage and current ratings for your application, and that they are equipped with overvoltage/overcurrent protection devices.

Their voltage and temperature ratings are appropriate for the voltages and temperatures they will be subjected to.

1.4 Selecting and Using High-Voltage Capacitor Discharge Tools

Discharging high-voltage capacitors is the most critical safety procedure. While bleeder resistors can provide passive protection, active discharge before handling capacitors is crucial. Specialized high-voltage capacitor discharge tools are designed to release the stored energy in a safe and controlled manner.When selecting a discharge tool, consider the following factors:

Voltage Rating: Ensure the tool's voltage rating is appropriate for the maximum voltage of the capacitors you are using. Using a tool with an underrated voltage can be extremely dangerous.

Resistance Value: The tool's internal resistance should be appropriate for the size of the capacitor. Too low a resistance can result in a sudden and destructive discharge; too high a resistance can result in a prolonged discharge.

Insulation: For high-voltage applications, the handle and leads must be adequately insulated.

Indicator: Many professional discharge tools include an indicator (such as an LED or voltmeter) to confirm when the capacitor has been safely discharged.

How to Use a Discharge Tool:

De-energize the Circuit: Always ensure that the power to the circuit containing the capacitor is turned off and locked out.

Connecting the Tool: Connect the discharge tool's leads to the capacitor's terminals. Maintain a safe distance, using only one hand whenever possible, and keeping the other hand away from conductive surfaces.

Wait for Discharge: Allow sufficient time for the capacitor to discharge. If your tool has an indicator light, wait until the indicator shows zero voltage or the LED turns off.

Verify with a Multimeter: After using the discharge tool, always verify the discharge by measuring the voltage with a multimeter. This is a final safety check.

(How to Discharge High Voltage Capacitors: Cheap DIY Capacitor Discharger)

1.5 Proper Use of a Capacitor Shorting Bar

A capacitor shorting bar, also known as a discharge bar or grounding bar, is another essential tool for safely discharging high-voltage capacitors. These tools are designed to quickly discharge capacitors by providing a direct, low-resistance path to ground.Key Features of Shorting Sticks:

Insulated Stick: The long, highly insulated stick keeps the user at a safe distance from high voltage.

Grounding Clamp: A heavy-duty clamp on one end connects to a reliable ground.

Discharging Tip: The other end has a conductive tip designed to make firm contact with the capacitor terminals.

Steps for Using a Shorting Stick:

Ensure Power is Off: Verify that the circuit is de-energized and isolated.

Grounding: Securely connect the stick's grounding clip to a known good ground point.

Discharging a Capacitor: Carefully touch the discharging tip to both terminals of a capacitor simultaneously. You may see sparks, indicating that the capacitor is discharging. Maintain contact for several seconds.

Verifying Discharge: As with discharge tools, always use a multimeter to confirm that the voltage between the capacitor terminals is zero.

Tip: Shorting sticks are designed for rapid discharge and may produce a lot of sparks.

1.6 Personal Protective Equipment for Handling High-Voltage Capacitors

When working with high-voltage capacitors, personal protective equipment (PPE) is an important line of defense against electrical hazards. Always ensure your PPE is rated for the operating voltage and in good condition.

Basic PPE includes:

Insulated gloves: Essential. Gloves should be rated for the voltage and inspected regularly for holes or damage. Always wear leather protective gloves over rubber insulating gloves to prevent mechanical damage.

Safety glasses or face shields: Protect your eyes and face from arcs, sparks, and potential explosions.

Flame-retardant (FR) clothing: FR clothing can significantly reduce burns in the event of an arc flash.

Insulated tools: Use tools with insulated handles to prevent current from flowing through your body.

Insulated footwear: Insulated boots provide an additional layer of protection against ground faults and prevent electric shock from step voltages or foot contact with live parts.

Safety belts: Used to prevent falls and ensure personal safety when working at heights.

1.7 Safety Precautions for Microwave Capacitors

Home microwave ovens contain a high-voltage capacitor that can store a potentially lethal charge even after power is removed. This capacitor is part of the magnetron circuit and typically operates at extremely high voltage (approximately 2000V AC, rectified to DC). Failure to take proper precautions when servicing a microwave oven can be extremely dangerous.Key Safety Precautions for Microwave Capacitors:

Unplug and Wait: Before opening the microwave oven, always unplug the power cord from the wall outlet and wait several minutes. This allows any residual charge to dissipate.

Manual Discharge: Even after waiting, the capacitor may still hold a dangerous charge. You must manually discharge it using a high-voltage discharge tool or a well-insulated screwdriver with a grounded jumper wire. Use the discharge tool to simultaneously touch both terminals of the capacitor.

Verifying Discharge: Before touching the capacitor, use a multimeter to confirm that it is fully discharged.

One-Hand Rule: When working inside a microwave oven, keep one hand in your pocket. This prevents your body from completing a circuit if you accidentally touch live parts.

1.8 Differentiating and applying safe capacitor types (X and Y capacitors)

In many electronic applications, especially those connected directly to the AC mains, safety capacitors are indispensable. These are specifically designed to fail safely, preventing electric shock or fire hazards. The two main types are X-capacitors and Y-capacitors, each serving a distinct purpose.

| Feature | X-Capacitors | Y-Capacitors |

|---|---|---|

| Connection | Line-to-line (across the mains) | Line-to-ground (or line-to-chassis) |

| Failure Mode | Fail short (fuse blows, circuit opens) | Fail open (prevents electric shock) |

| Purpose | Suppress differential mode interference | Suppress common mode interference, provide safety |

| Risk | Fire hazard if not properly fused | Electric shock hazard if fails short |

Y capacitors, on the other hand, are connected between the line and ground (or chassis). They are essential for suppressing common-mode interference and, more importantly, provide protection against electric shock. If a Y capacitor fails, its design opens, preventing a dangerous short circuit to the chassis and potentially causing an electric shock. For this reason, they are often referred to as "line-to-ground safety capacitors."

Safety Tip: Never substitute standard capacitors for X or Y safety capacitors. Their unique failure modes are critical to safety compliance.

1.9 Safe Storage Practices for High-Voltage Capacitors

Proper storage of high-voltage capacitors is crucial to maintaining their integrity and ensuring safety. Improper storage can lead to degraded capacitor performance, shortened service life, and even dangerous failures when the capacitor is ultimately placed in service.

The following are key environmental requirements for storing high-voltage capacitors:

Temperature Control: Store capacitors within the specified temperature range, typically room temperature. Extreme heat or cold can degrade the dielectric material and electrolyte.

Humidity Control: High humidity can lead to moisture absorption, especially in electrolytic capacitors, which can cause corrosion and premature failure. Store capacitors in a dry environment.

Cleanliness: Keep the storage area free of dust, dirt, and corrosive fumes. Contaminants can cause terminal bridging or insulation degradation.

Physical Protection: Store capacitors in their original packaging or protective containers to prevent physical damage, such as dents or bent leads.

Discharged State: Ideally, capacitors should be stored in a fully discharged state. If charged storage is necessary (for example, for a specific application), ensure the capacitors are clearly labeled and stored in a secure, accessible area.

1.10 Interpretation of the IEC 60831 Capacitor Safety Standard

In addition to national regulations such as OSHA, international standards also play a vital role in ensuring the safety and reliability of electrical components. IEC 60831 (Fixed Power Capacitors for AC Systems with Rated Voltages Up to 1000 V) is a good example, providing detailed requirements for the design, testing, and safe operation of power capacitors.

Key aspects of IEC 60831 typically include:

Overvoltage Circuit Breaker: Requires an internal overvoltage circuit breaker to safely isolate the capacitor in the event of an internal fault, preventing rupture.

Discharge Device: Specification of an internal or external discharge device to ensure safe discharge of the capacitor after disconnection from the power supply.

Temperature Class: Defines the ambient temperature range within which safe operation is permitted.

Dielectric Strength: Specifies the dielectric withstand voltage capability of the insulation.

Endurance Testing: Outlines tests to ensure that the capacitor can withstand the expected operating stresses over its service life.

Compliance with standards such as IEC 60831 is crucial for manufacturers and users alike, as it ensures capacitors meet stringent safety and performance standards. This helps improve the overall reliability and safety of electrical systems worldwide.

Frequently Asked Questions

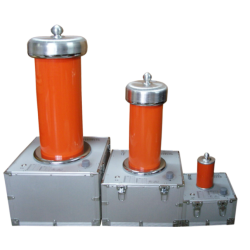

What are high-voltage capacitors?A high-voltage capacitor is a device that can store and release electrical energy and is commonly used in various high-voltage DC and AC circuits. Unlike ordinary capacitors, high-voltage capacitors are capable of operating at high voltages and have greater capacitance and higher voltage ratings. These devices typically use metallized polypropylene film (MPP) or metallized polypropylene (MPC) as a dielectric, enabling stable and reliable energy storage during operation.

What are the signs of a failing high-voltage capacitor?

Common signs of a failing high-voltage capacitor include visible swelling or leakage, a burning odor, an audible hissing or humming sound, and degraded circuit performance. If you notice any of these signs, immediately disconnect the circuit from power and consult a qualified professional.

How should I dispose of old high-voltage capacitors?

High-voltage capacitors, especially those that may contain polychlorinated biphenyls (PCBs), must be disposed of according to local environmental regulations. Contact your local waste management agency or a specialized hazardous waste disposal company for proper guidance.

How should I select and use a high-voltage capacitor?

1. Select the appropriate capacitance and voltage rating.

When selecting a high-voltage capacitor, determine the required capacitance and voltage rating based on the actual circuit requirements. If the capacitance is too small or the voltage rating is too low, it may not meet the circuit's needs, while if it is too large, it will result in waste and unnecessary costs.

2. Ensure safe use of the capacitor.

When using high-voltage capacitors, pay attention to safety issues. Because high-voltage capacitors can store large amounts of electrical energy, improper use and maintenance can pose a risk to personnel and equipment. Therefore, certain safety measures are required when using high-voltage capacitors, such as preventing short circuits and using specialized insulating materials.

3. Technical support and after-sales service.

Finally, when selecting a high-voltage capacitor, consider the supplier's technical support and after-sales service. Reputable suppliers can provide comprehensive technical support and after-sales service to ensure stable operation and a long life for the high-voltage capacitor under normal operating conditions.