Polymer Capacitors: Advantages & Applications

What is a Polymer Capacitor?

Polymer capacitors are advanced electrical components made with a solid electrolyte instead of a liquid one. These capacitors use conductive polymers for better performance, including lower equivalent series resistance (ESR) and longer life spans compared to traditional electrolytic capacitors. This unique design makes them ideal for applications requiring stability and high efficiency. Whether used in consumer electronics or industrial machinery, polymer capacitors play a crucial role in providing reliable energy storage.

What Are Polymer Capacitors Used For?

Polymer capacitors have a wide range of applications due to their advanced performance characteristics.1. Consumer Electronics

Polymer capacitors are frequently found in consumer electronics such as smartphones, laptops, tablets, and gaming consoles. These devices require efficient power supply circuits that can handle fluctuations in power and filter out noise. Polymer capacitors excel in these situations due to their low ESR, which ensures that power is delivered smoothly to the device’s components. This leads to improved battery life, faster charging, and better overall performance.

2. Power Supplies and Voltage Regulation

Polymer capacitors are essential components in power supplies and voltage regulators. In these applications, the capacitors are responsible for filtering out high-frequency noise and stabilizing the voltage output.

Switching power supplies, in particular, benefit from polymer capacitors because of their ability to handle high ripple currents. These power supplies convert AC power to DC, and during this process, large current fluctuations can occur. Polymer capacitors, with their low ESR, can absorb these fluctuations without generating excessive heat, making them more efficient and reliable in power regulation circuits.

3. Automotive Electronics

Automotive systems require components that can withstand high temperatures, vibration, and extreme conditions. Polymer capacitors are used in automotive applications such as engine control units (ECUs), infotainment systems, and power distribution modules. Their ability to maintain performance in temperatures ranging from -55°C to 125°C makes them highly suited for automotive environments, where temperature variations are common.

Moreover, polymer capacitors are also employed in electric and hybrid vehicles, where efficient energy storage and management are crucial. In these applications, the capacitors help in managing the power supply between the battery and the motor, ensuring smooth acceleration and regenerative braking.

4. Telecommunications

In telecommunications equipment, such as routers, servers, and base stations, polymer capacitors are used for signal filtering and voltage stabilization. These devices require uninterrupted operation, often running continuously for years without downtime. The high reliability and long lifespan of polymer capacitors make them a preferred choice in this field.

The low ESR and high-frequency handling capabilities of polymer capacitors are especially valuable in telecommunications systems, where maintaining signal integrity and reducing noise are critical for efficient data transmission. Polymer capacitors help in achieving clear and stable signals, contributing to the overall performance and reliability of telecom infrastructure.

5. Industrial Machinery

Polymer capacitors are also used in various types of industrial machinery, especially those with high-frequency switching circuits. In industrial environments, equipment often operates in harsh conditions, where temperature, humidity, and vibration can affect performance. Polymer capacitors are highly durable and can withstand these challenging conditions, making them ideal for use in industrial applications.

They are commonly used in motor controllers, power inverters, and other systems that require efficient energy conversion and power management. Their long lifespan ensures that industrial machines run reliably for extended periods, reducing maintenance costs and downtime.

6. Medical Devices

Medical devices, such as diagnostic equipment, imaging systems, and portable medical devices, rely on the precise and stable operation of electronic components. Polymer capacitors are used in these devices due to their ability to provide consistent power and filter out noise, ensuring that the equipment functions accurately.

For example, in MRI machines and ultrasound systems, the capacitors help regulate power and minimize interference, leading to clearer images and more accurate diagnoses. The reliability and stability of polymer capacitors make them essential in medical devices where precision and performance are critical.

7. Audio and Video Equipment

Audio and video equipment, such as amplifiers, mixers, and home theater systems, can also benefit from polymer capacitors. Their low ESR helps improve sound quality by providing cleaner and more stable power, reducing unwanted noise and distortion in audio signals.

For video equipment, polymer capacitors help in maintaining smooth video output by stabilizing the power supply. This results in a clearer picture with fewer interruptions or visual artifacts. Professionals in the music and film industries often rely on polymer capacitors in their equipment to ensure that their recordings and productions meet the highest quality standards.

8. Renewable Energy Systems

In renewable energy systems, such as solar panels and wind turbines, polymer capacitors are used to store and manage the energy generated. These systems require components that can handle the fluctuating power levels that come from variable energy sources. Polymer capacitors, with their ability to handle high ripple currents and stable capacitance, play a crucial role in ensuring the smooth conversion and storage of energy.

Are Polymer Capacitors Polarized?

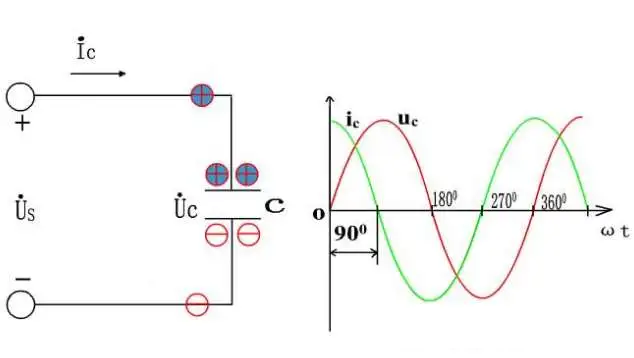

Yes, most polymer capacitors are polarized. This means they have a positive and negative lead, and it’s essential to install them correctly in a circuit. If the polarity is reversed, it can lead to malfunction or damage. While the polarization adds a layer of care in handling, it helps ensure the capacitor works optimally by directing the current flow in the right direction.Advantages of Polymer Capacitors

1. Lower ESR (Equivalent Series Resistance)One of the most important advantages of polymer capacitors is their extremely low ESR. Low ESR reduces the internal resistance, which improves the capacitor’s overall efficiency. In high-frequency circuits, where power stability is critical, polymer capacitors help ensure smooth operation without excessive power loss.

2. Higher Ripple Current Tolerance

Polymer capacitors can handle higher ripple currents compared to their liquid electrolyte counterparts. Ripple current is the AC component present in a DC circuit, and it can generate heat within the capacitor. Since polymer capacitors have a lower ESR, they dissipate less heat.

3. Longer Lifespan

Another key benefit of polymer capacitors is their durability. Unlike traditional electrolytic capacitors, which use liquid electrolytes prone to drying out over time, polymer capacitors have a solid electrolyte that doesn’t evaporate or degrade. This design gives polymer capacitors a significantly longer life span, often lasting 10-20 years depending on the operating environment. As a result, they reduce the need for frequent replacements, contributing to overall cost savings and better reliability.

4. Stability in High-Temperature Environments

Polymer capacitors are also well-suited for high-temperature applications. They maintain their performance even under harsh conditions, such as those found in automotive electronics or industrial machines. With a higher thermal tolerance, polymer capacitors perform consistently across a wide temperature range, often between -55°C and 125°C, making them a better option for challenging environments.

5. Compact Size

In today’s electronics, space is always a concern. Polymer capacitors offer excellent capacitance values in a relatively small package. This compact size makes them ideal for use in modern electronics, where devices are becoming smaller and more powerful.

6. Excellent Frequency Characteristics

Polymer capacitors perform exceptionally well in high-frequency applications due to their low ESR and stable capacitance. This makes them ideal for use in power conversion and filtering applications, such as DC-DC converters and voltage regulators. Their ability to handle high-frequency noise and maintain stable performance ensures smoother operation in circuits that require clean, regulated power.

Disadvantages of Polymer Capacitors

While polymer capacitors are highly efficient and reliable, they do come with a few limitations. Understanding these drawbacks helps you decide if they’re suitable for your application.1. Limited Voltage Range

One of the main disadvantages of polymer capacitors is their limited voltage rating. While they offer excellent performance in low to medium voltage applications, their voltage range typically falls between 2.5V and 125V. This limitation means they are not suitable for circuits requiring very high voltages, where other types like ceramic or electrolytic capacitors might be better choices.

2. Higher Cost

Polymer capacitors tend to be more expensive than traditional electrolytic capacitors. The higher cost comes from their advanced design and the materials used in manufacturing. However, it’s essential to consider the long-term value they offer, such as extended lifespan and better performance, which often justify the initial investment, especially in critical applications.

3. Sensitivity to Over-Voltage

While polymer capacitors are generally durable, they can be sensitive to over-voltage conditions. Operating the capacitor at voltages higher than its rated value can lead to damage and reduced lifespan. In extreme cases, over-voltage can cause the capacitor to fail, making it crucial to ensure that the operating voltage stays within the recommended range.

How Long Do Polymer Capacitors Last?

The lifespan of a polymer capacitor is generally much longer than traditional electrolytic capacitors. On average, they can last up to 10-20 years depending on operating conditions such as temperature and voltage stress. Unlike liquid-based electrolytic capacitors, they are not prone to drying out, which gives them better longevity and reliability in the long run. This longer life reduces the need for frequent replacements, which is a huge advantage in critical systems.Are Polymer Capacitors Good for Audio?

Yes, polymer capacitors can be a good option for audio applications. Their low ESR contributes to better sound quality by providing cleaner and more stable power. This is particularly beneficial in high-fidelity audio systems, where every small improvement in power stability can enhance the overall sound experience. However, they are not always the first choice for every audio system, as preferences vary depending on the specific sound characteristics desired.Polymer Capacitors vs Electrolytic Capacitors

When comparing polymer capacitors to electrolytic capacitors, the most noticeable differences are in performance and lifespan. Polymer capacitors generally have lower ESR, which translates to better efficiency and less heat generation. This makes them a superior choice for high-frequency and high-ripple current applications. In contrast, electrolytic capacitors are often chosen for higher voltage applications due to their broader voltage range. In addition to this, there are some other differences between them:First of all, from a structural point of view, polymer capacitors use conductive polymer materials as dielectric materials, which replace the traditional electrolyte, thus forming a solid electrolyte. This structural difference allows polymer capacitors to have higher temperature stability and longer service life. In contrast, electrolytic capacitors use liquid or paste electrolytes, which can cause some problems in high-frequency circuits, such as electrolyte drying, leakage or explosion.

In terms of performance, polymer capacitors have a lower equivalent series resistance (ESR), which means they perform better in high-frequency circuits and filter out ripple current and noise more efficiently. In addition, because there is no liquid electrolyte, polymer capacitors have a significant improvement in safety, not easy to leak, and low risk of explosion. These characteristics make polymer capacitors particularly suitable for portable electronic devices and high-density assembly applications.

From the application point of view, the use of polymer capacitors and electrolytic capacitors is also different. For example, aluminum polymer capacitors are widely used in circuits requiring high frequency response because of their excellent electrical properties and safety. Electrolytic capacitors are still used in some cost-sensitive applications due to their lower cost.

When to Use a Polymer Capacitor?

While polymer capacitors offer excellent performance, polyester capacitors have their niche. They are well-suited for situations requiring stable capacitance in the presence of fluctuating temperatures. Known for their reliability and consistent performance over a wide range of conditions, polyester capacitors are often used in timing circuits and coupling/decoupling applications. They excel where accuracy and consistency matter but may not match the low ESR benefits of polymer capacitors.What Is the Voltage Rating of Polymer Capacitors?

The voltage rating of polymer capacitors typically ranges between 2.5V and 125V, depending on the specific type and design. This makes them suitable for low to medium voltage applications. While their voltage range is not as extensive as other types, such as ceramic or electrolytic capacitors, they offer excellent performance within their operating range. It’s important to always check the voltage rating and ensure that it aligns with your circuit’s requirements.

What Is the Difference Between Tantalum and Electrolytic Capacitor?

MaterialTantalum capacitor is a kind of solid state electrolytic capacitor, its positive electrode is made of tantalum metal, and is covered by oxide, the negative electrode is made of tungsten, and the positive electrode of tantalum direct contact. The positive electrode of the electrolytic capacitor is usually a transparent aluminum oxide layer, which is composed of a layer of metal foil and electrolyte inside, and the negative electrode is a metal shell.

Capacity and accuracy

The capacity of tantalum capacitors is usually between a few micromethods and several hundred micromethods, and the accuracy can reach one percent or more. In contrast, electrolytic capacitors have a larger capacity, which can reach thousands of micromethods, and are also better in terms of accuracy.

Stability

Tantalum capacitors have a much lower temperature coefficient than electrolytic capacitors, so they are more stable. Tantalum capacitors are not affected by voltage, have a long service life and a lower maintenance rate than electrolytic capacitors. Electrolytic capacitors are affected by ambient temperature, pressure and other factors, and their service life is relatively short, easy to be damaged by overpressure or overtemperature.

Operating frequency

Tantalum capacitors have a wide operating frequency range, up to a few MHz or even higher, which is very suitable for high-frequency applications. The electrolytic capacitor is suitable for low operating frequency occasions, usually not more than a few hundred kHz.

Cost

The manufacturing cost of tantalum capacitor is high, and the price is relatively high. The manufacturing cost of electrolytic capacitors is relatively low, and the price is relatively low.

Voltage leakage current

The voltage leakage current of tantalum capacitors is often very small, generally less than A few microamperes (A), which makes tantalum capacitors widely used in high-precision circuits.

Frequency response

Tantalum capacitors are highly responsive to high frequency signals due to their short charge storage time. This makes tantalum capacitors widely used in high-frequency circuits.

Life

Tantalum capacitors usually have a long life, while electrolytic capacitors have a short life.

Polarity

Tantalum capacitors are usually divided into two types: polar and non-polar. Polar tantalum capacitors need to pay attention to positive and negative polarity, while non-polar tantalum capacitors have no positive and negative polarity.

What Type of Capacitor Lasts the Longest?

Among all capacitor types, polymer capacitors are considered some of the longest-lasting, thanks to their solid-state design. Unlike traditional capacitors that use a liquid electrolyte, polymer capacitors are less prone to failure from electrolyte leakage or drying. Ceramic capacitors also have a long lifespan, but polymer capacitors provide better performance in specific high-stress environments. Choosing the right type of capacitor depends on your application, but in general, polymer capacitors offer excellent longevity.

Statement

All articles (images, texts, audio) on this site are uploaded and shared by users, or integrated from relevant internet sources, only for user's learning. If your rights are violated, please contact the administrator to delete! Link to this article: https://www.jinftry.com