What are backplane connectors? How are they used?

What Are Backplane Connectors?

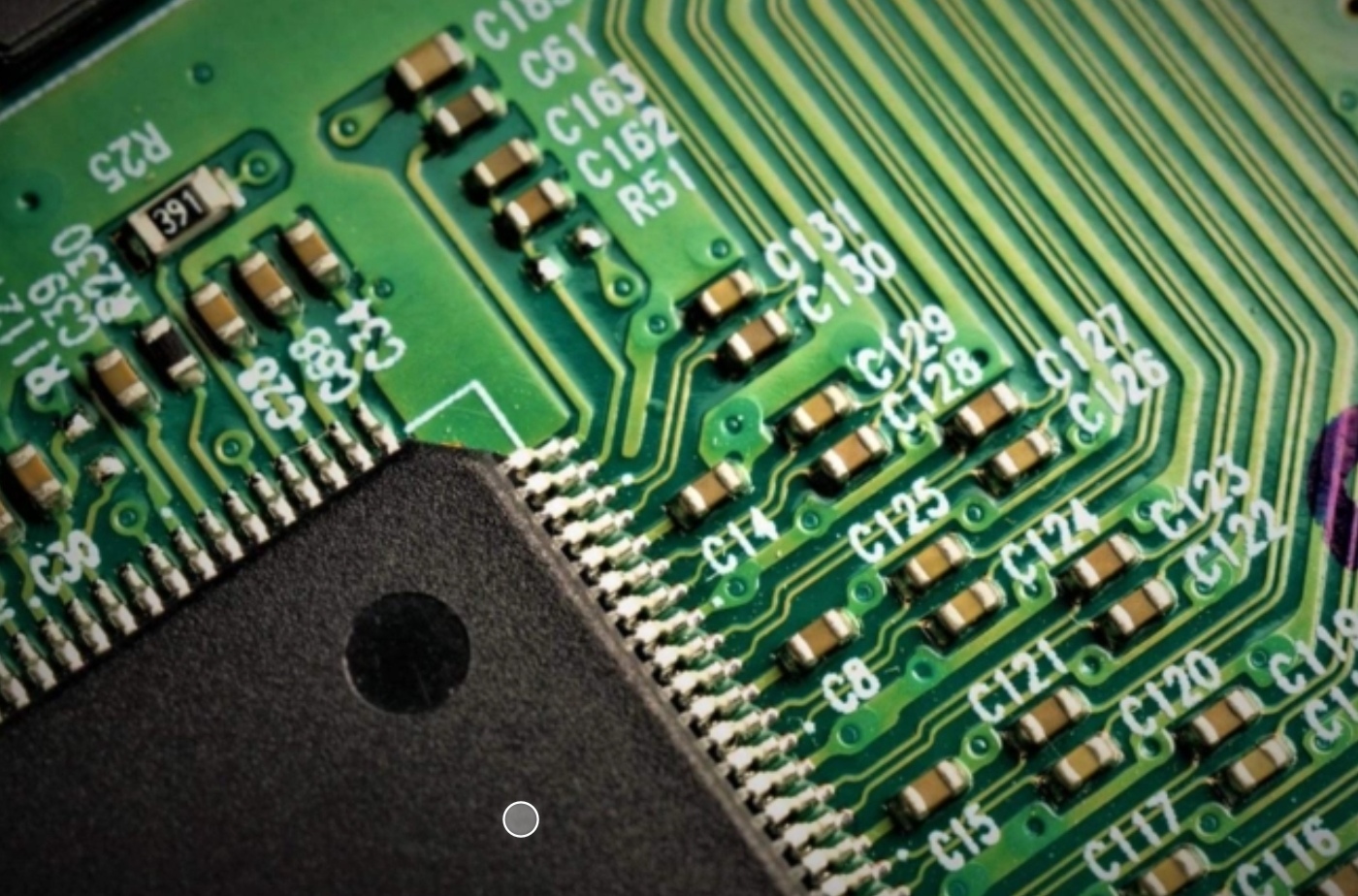

Backplane connectors are used to interconnect multiple printed circuit boards (PCBs) in a backplane system. They replace complex cabling with a more structured and reliable connection method. This simplification in design leads to enhanced performance and greater reliability.Types of Backplane Connectors:

1. Standard Backplane Connectors

These are basic connectors used in applications where highspeed data transfer is not critical. They provide essential connectivity without the advanced features needed for high-performance systems.

2. High-Speed Backplane ConnectorsDesigned for systems that require rapid data transfer. These connectors handle high data rates while minimizing signal degradation, making them crucial in advanced computing and networking equipment.

3. Power Backplane ConnectorsSpecialized for handling higher power loads. These connectors are typically found in industrial applications and power distribution systems where robust power handling is essential.

Manufacturers like Molex offer a wide array of backplane connectors to meet the needs of different applications. Each type is designed to optimize performance for specific use cases, whether it’s for standard connectivity or highspeed data transfer.

What Are the Advantages of Backplane Connectors?

Backplane connectors offer numerous advantages over traditional cabling and interconnect solutions. Here are some key benefits:Space Efficiency

By consolidating multiple connections into a single backplane, these connectors significantly reduce the space required for wiring. This allows for more compact and efficient designs. This space-saving attribute is especially beneficial in systems where space is a premium.

High-Speed Performance

Backplane connectors are designed to facilitate highspeed data transmission with minimal signal loss. This capability is essential for modern computing environments that demand fast and reliable data communication.

Simplified Maintenance

Systems using backplane connectors are easier to maintain and upgrade. PCBs can be replaced or added without the need for extensive rewiring. This modularity simplifies both initial setup and future upgrades.

Enhanced Reliability

By reducing the number of individual physical connections, backplane connectors lower the risk of connection failures. This results in improved overall system reliability, which is crucial in applications where uptime is critical.

How Does a Backplane Connector Work?

Backplane connectors function as the central hub for connecting multiple PCBs. They facilitate communication and power distribution between the connected boards. Here’s a simplified overview of their operation:PCB Interface

Each PCB has a mating interface that connects to the backplane connector. This interface can be a card edge, pin-and-socket, or another type of connector. This interface ensures a secure and reliable physical connection.

Signal Transmission

Once the PCBs are connected to the backplane, signals can be transmitted through conductive pathways embedded in the backplane. These pathways provide efficient data and power distribution between the PCBs.

Mechanical Support

Besides providing electrical connections, the backplane also offers mechanical support. It ensures that the connected PCBs are stable and properly aligned. This mechanical support helps maintain the integrity of the connections over time.

Highspeed backplane connectors are engineered to minimize signal interference and crosstalk. This design consideration is crucial for maintaining signal integrity in applications that involve high-frequency data transmission. By ensuring clear and uninterrupted signal paths, these connectors play a vital role in the performance of highspeed electronic systems.

What Are the Considerations When Selecting a Backplane Connector?

Selecting the right backplane connector for your application involves several important considerations. Here are key factors to keep in mind:Speed and Bandwidth Requirements

One of the most critical factors is whether the connector can support the data rates your application requires. Highspeed backplane connectors are essential for applications where fast data transmission is crucial. Ensure that the connector meets or exceeds the necessary speed and bandwidth specifications.

Mechanical Fit

The physical design of the connector must align with the system’s mechanical constraints. This includes factors like board thickness, connector size, and alignment requirements. The connector must fit well within the available space and align properly with the PCBs.

Electrical Performance

Consider the connector’s ability to handle the required voltage and current levels without significant signal degradation. Ensure that it provides stable and reliable connections under the electrical conditions of your system.

Environmental Factors

Account for the operating environment where the connector will be used. This includes temperature ranges, humidity levels, and potential exposure to harsh conditions. The connector should be rated to perform reliably under these environmental conditions.

Cost and Availability

Balance performance needs with budget constraints. Also, consider the availability of the connector. Ensure that the chosen connector is readily available and cost-effective. This consideration helps avoid potential delays in your project due to supply issues.

Manufacturers like Molex offer a wide range of backplane connectors to suit different applications and performance needs. Selecting the right connector involves evaluating these factors to ensure optimal performance and reliability for your specific application.

What Are the Common Applications of Backplane Connectors?

Backplane connectors are used across various industries and applications. Their versatility and reliability make them suitable for many different uses:1. Data Centers like servers, storage systems, and networking equipment in data centers. They support the high data transfer rates required for modern data processing and storage.

2. Used in switches, routers, and other communication equipment, backplane connectors enable reliable data transmission in telecommunication networks. They ensure efficient handling of high data volumes and rapid communication.

3. In industrial control systems, backplane connectors provide connectivity for sensors, actuators, and controllers. They enable seamless integration of various components in automation systems, improving operational efficiency.

4. In aerospace and defense applications, backplane connectors are essential for ruggedized systems. These systems require reliable performance under harsh conditions, and backplane connectors provide the necessary robustness and stability.

These applications highlight the versatility and importance of backplane connectors in modern technology. Their ability to provide reliable, highspeed connections makes them indispensable in many critical systems.

How Does Backplane Connector Pitch Affect Performance?

The pitch of a backplane connector, which refers to the spacing between pins, has a significant impact on performance. Here’s how:Signal Integrity

Smaller pitch connectors reduce the distance between pins. This minimizes signal degradation and crosstalk, which is crucial for maintaining signal integrity in highspeed data transmission. Reducing these issues helps ensure clear and accurate signal transmission.

Density

A smaller pitch allows for higher connector density. This means more connections can be made in a compact space, which is beneficial for applications with limited space. Higher density connectors enable more complex and capable systems in a smaller footprint.

Manufacturing Complexity

While smaller pitch connectors offer performance advantages, they can also increase manufacturing complexity. Tighter tolerances are required, which can raise production costs. Balancing the benefits of smaller pitch with manufacturing feasibility is important.

Selecting the appropriate pitch involves balancing these factors to achieve the desired performance while managing manufacturing constraints and costs. Ensuring the right pitch helps optimize the performance and reliability of the backplane connector in your application.

How Do I Troubleshoot Issues with Backplane Connectors?

Troubleshooting backplane connector issues involves several steps to identify and resolve problems effectively:1. Visual Inspection: Start with a thorough visual inspection of the connectors and

PCBs. Look for any physical damage, misalignment, or debris that might be affecting the connections. This step can often reveal obvious issues that are easy to fix.

2. Signal Testing: Use diagnostic tools to test the signal integrity of the connections.

Identify any disruptions or losses in the signal. Signal testing can help pinpoint specific areas where the connection may be failing or degrading.

3. Connectivity Check: Ensure that all connectors are properly seated and locked in

place. Loose connections can cause intermittent issues and signal degradation. Verify that each connection is secure and correctly aligned.

4. Environmental Assessment: Evaluate the operating environment for factors like

temperature, humidity, and potential exposure to harsh conditions. Environmental factors can impact the performance of backplane connectors. Ensure that the connectors are operating within their specified environmental conditions.5. Replacement: If issues persist after troubleshooting, consider replacing the connector or the affected PCB. Determine if the problem lies with the hardware itself. Replacing faulty components can resolve persistent issues and restore proper functionality.

Regular maintenance and monitoring can prevent many common issues with backplane connectors. If you found your backplane connectors are troubleshoot, and it can't repair by yourself, then you can buy a new one from Jinftry. Jinftry is a leading electronic components distributor in Asia, we have various kind of components for your choice. Contact us right now to get your parts!